FMEA E-Training

Professional FMEA training for your team.

Learn in three simple steps how to conduct effective Failure Mode and Effects Analysis with Smart CAQ and optimize your quality processes.

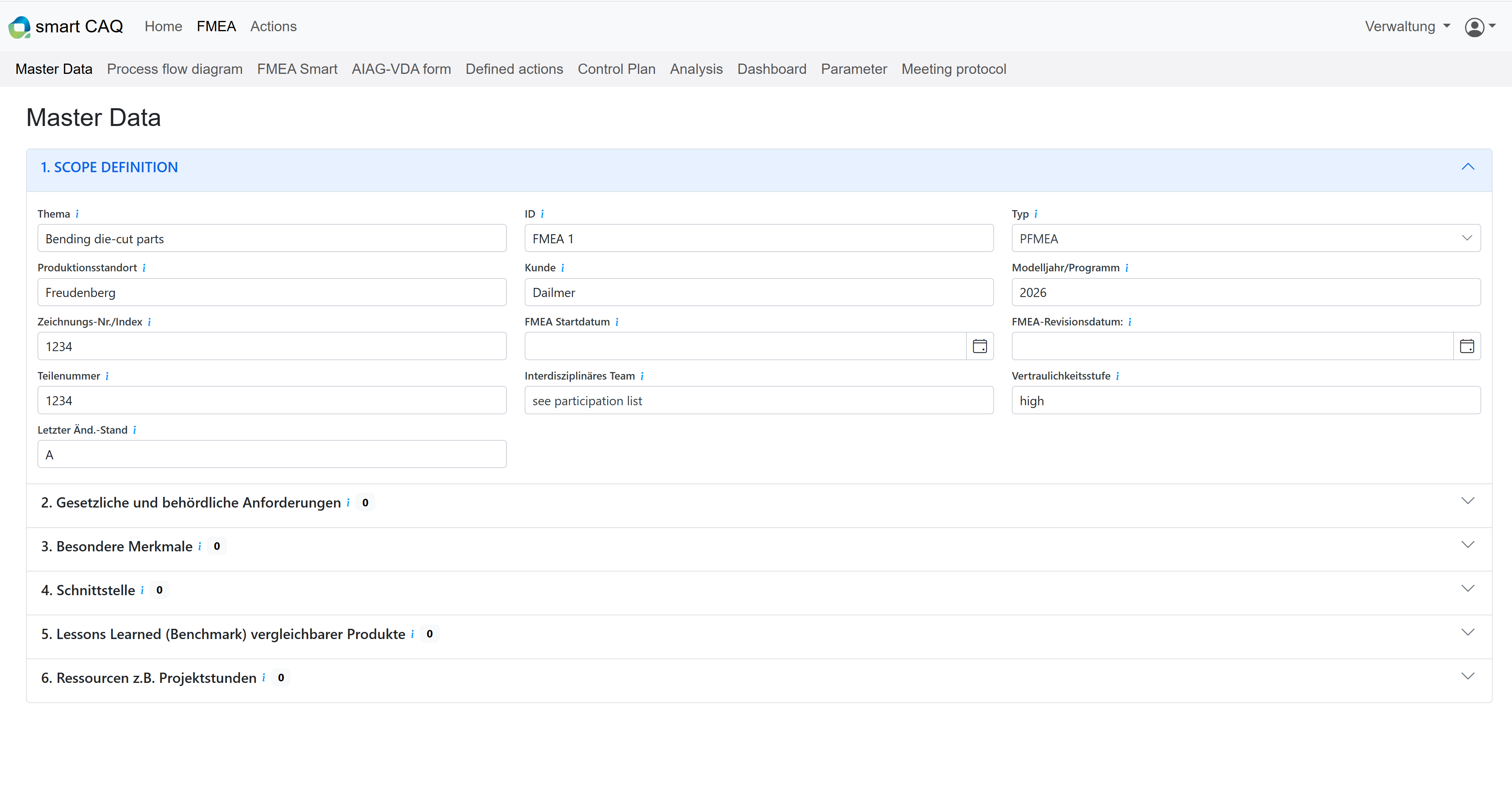

Step 1 of 3

Planning and Preparation

Learn how to capture the basic master data and information for your FMEA. Define all important details from plant location to regulatory requirements.

- Enter master data and basic information

- Define dates and confidentiality levels

- Document regulatory requirements and interfaces

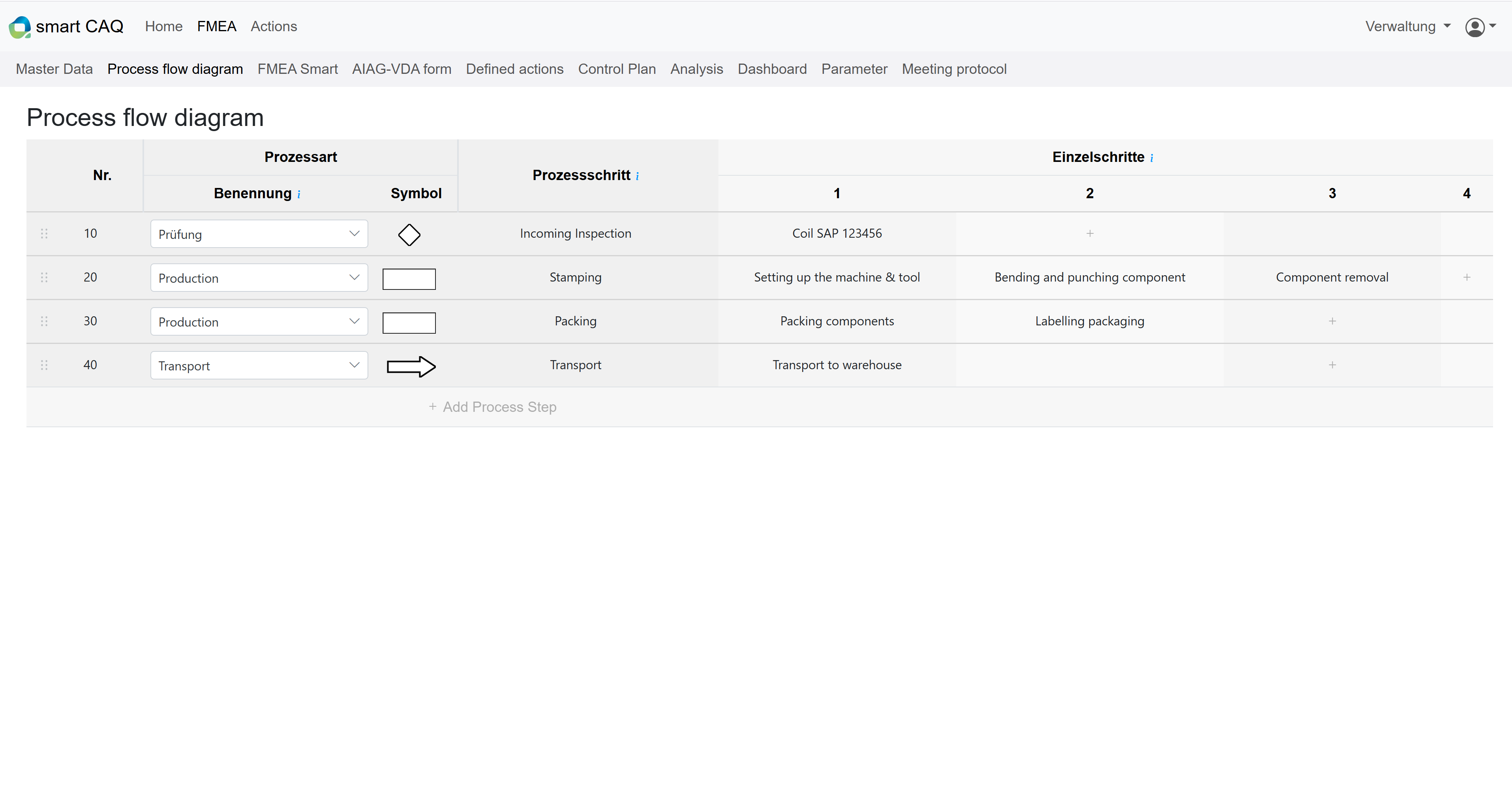

Step 2 of 3

Structural Analysis

Create a process flow diagram and describe the sequence of your manufacturing steps. Define process steps and divide them into detailed sub-processes.

- Define and categorize process steps

- Create sub-processes for each process step

- Automatic transfer to FMEA Smart Tab

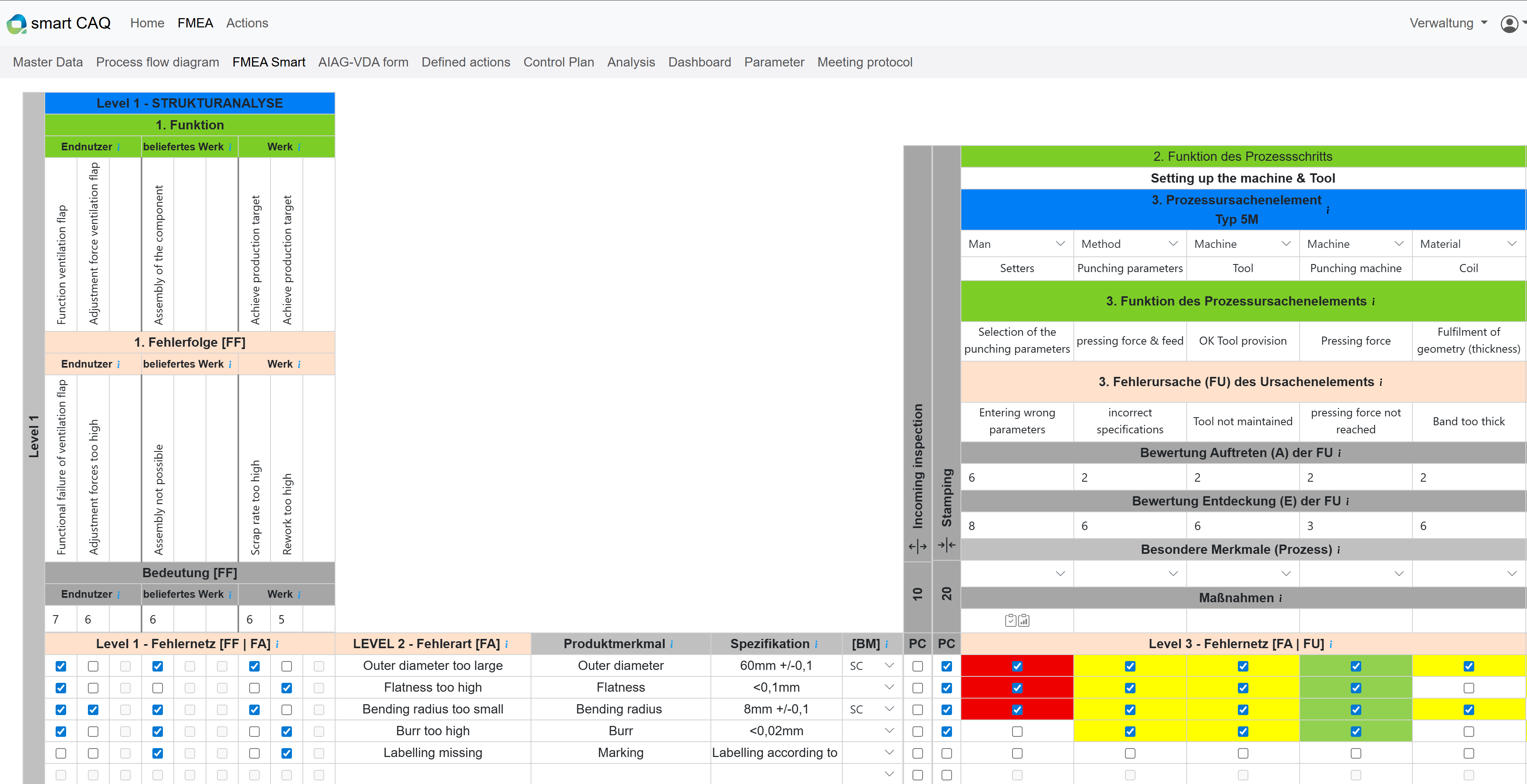

Step 3 of 3

Define Your Product

Define your product characteristics, failure modes and their effects. Analyze failure causes using the 5M method and systematically evaluate risks.

- Define characteristics, specifications and failure modes

- Assess failure effects and determine severity

- Perform 5M analysis and risk assessment

Ready for the next step?

Get started with Smart CAQ today and optimize your FMEA processes.